What Is The Best Glue For Shoe Sole Repair?

.webp)

What is the best glue for shoe sole repair - Not all shoe glues are the same! And, while most all-purpose glue producers will include a little shoe logo in the corner of the package, choosing your pick is far more difficult. Several elements must be considered: the quality of the hold over time, the section of the shoe to be mended - whether structural or not, the degree of the rip, the kind of material, and the drying time...

Finally, there is one certainty: the best shoe glues are not always the ones we think of, and the top brands are quite difficult to buy in offline stores. But We located them for you!

5 Recommendations for shoe glue that can fix shoe sole

To be able to repair damaged shoes, it is necessary to glue shoes that have good quality, strong adhesion, and flexibility, below we have summarized a list of shoe glue brands that can be a recommendation for you in repairing damaged shoes.

1. Special Leather Pattex

Pattex, unlike the other manufacturers in our comparison, does not specialize in shoe glues. Above all, it has created glues for the general population, including the forerunner of the famed. This low-cost shoe glue is especially ideal for all leather goods.

A few points must be clarified while discussing leather shoe glue. One of the benefits of this form of shoe adhesive is that it does not cause harm.

A few points must be clarified while discussing leather shoe glue. One of the benefits of this form of shoe glue is that it does not harm the leather, which is a living substance that is sensitive to certain solvents. This does not indicate that these glues are weaker; their formula has merely been modified.

However, we can still distinguish between glues for leather shoes that are strong enough to accomplish structural repairs at the level of the sole, heel, or other pressure points, and those that will mostly be used for aesthetic touch-ups outside of the shoe's pressure points.

2. Loctite Superglue PowerFlex

Loctite is an American brand, Because of its non-colored substance, excellent grip, and accurate applicator, this flexible glue is great for shoes.

Whereas Pattex, with its softer leather composition, was more reserved for aesthetic usage and touch-ups, Loctite is an exceptionally strong super glue type adhesive that we cannot suggest on all materials. For leather, for example, it is best to test a little amount on an inconspicuous portion of the shoe to verify that it does not discolor or change its texture.

3. Sader Neoprene

Sader is a shoe adhesive whose active ingredient is neoprene, synthetic rubber in liquid form that is valued for its long-lasting grip, low cost, and flexibility. Three features that make it a popular shoe repair product. Because of the nature of neoprene glue, we like to use it mostly for minor fits.

Neoprene, commonly known as contact glue, is utilized in a variety of industrial applications, including shoe glue. Its key benefit is that it is made up of solvents that are not very harsh on materials, allowing it to be compatible with a wide range of surfaces without causing damage.

It is available in the form of a clear gel that dries clear and is easier to apply than liquid neoprene glue.

Neoprene glue has an excellent grip on its own, due to its flexibility: it is also known as liquid rubber, and it takes on the qualities of this material once dried. One of the most crucial factors to consider when selecting a decent shoe glue is flexibility.

4. Shoe Goo

Shoe Goo functions similarly to Cleopatra's shoe glue for paper. It is present in every house in the United States, and its distinct scent - highly distinctive and undeniably perfumed - is also tied to the deep emotional relationship they have with this recipe. Its attraction, however, is not only nostalgic. If this almost century-old composition continues to function, it is because it still provides numerous benefits at a very low cost: it is the cheapest shoe adhesive in the technical glue category.

Shoe Goo was formerly the only shoe glue that dried with no residue, giving it a significant edge over its competitors, who were probably the first yellowish and gelatinous neoprenes. It has a unique recipe since it is highly liquid and transparent.

It is therefore easier to apply. In terms of strength and durability, it's a bit difficult to assess, because it's a difference in use. In Europe, our vision of repair is that it must be permanent: we, therefore, favor superglues, for example.

The Shoe Goo is part of another logic. This shoe glue, which lacks a little flexibility, will eventually come undone after a few months and it will be necessary to start the repair again.

5. Gorilla Glue

Gorilla Glue is another well-known brand from North America that has made a name for itself in the European market. Their shoe adhesive is a gel-like super glue that comes in a little bottle and costs significantly more than typical. So, what exactly makes it a such good value for money? Its price and astonishing adaptability have scarcely been matched.

To be honest, Gorilla Glue has it all. This shoe glue dries rapidly and produces excellent results in a matter of minutes, even without the need for pliers. As a result, there is no need to arrange its repair in advance.

It is also one of the most adaptable glues: its mild solvent formula is good for both leather and less fragile fabrics, it is totally clear, without residue or texture, and its hold is excellent regardless of the supports.

In reality, it is an excellent fundamental strategy for small-scale home shoemaking projects. Because it gripped other materials, it is the recommended adhesive for specialty shoemaking. Its excellent adherence to metal makes it ideal for safety shoes, for example, and its excellent results on wood allow it to restore old-school shoes with worn-out soles.

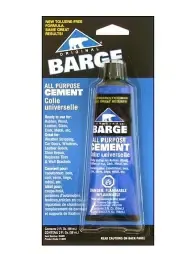

6. Barge All Purpose

Not everyone wants to bother with glue for such a specific use as shoemaking. If you're looking for a shoe glue that's just as good for everyday hassles, the Barge All Purpose is an Anglo-Saxon favorite, for all the right reasons.

This glue is of the polymer cement type. If it is not originally intended as a shoe glue, it is particularly indicated, thanks to several advantages.

First, unlike other cement-type adhesives, it offers a very attractive elasticity rate which makes it more resistant to repairing parts subjected to significant stress – such as shoes.

Its ultra-strong formula also has a very interesting hold over time which holds moisture very well, whereas neoprenes, for example, tend to lose effectiveness.

Its semi-liquid gel formula and precision applicator are also ideal for repairing shoes. Some all-purpose glues have a rounded tip that is too open, which makes precision work difficult.

Buying guide: everything you need to know about shoe glues before buying

Before buying the right shoe glue, as well as understand the difference between each shoe glue, the result of the gluing process, and the level of safety for your shoes

- The different types of glues for shoes

- Safety instructions

- Tips for getting a better result

The different types of glues for shoes

To simplify to the extreme, we can distinguish three types of glues for shoes among those most often offered on the consumer market – here we exclude industrial glues, which are not accessible to everyone for technical reasons. or security.

Neoprene, or contact glue, and a synthetic rubber whose main feature is to be particularly flexible. This is a sought-after property in shoemaking, since the different components of the shoe must be able to deform to follow the movement of the foot. It performs better on plastic and leather than other materials and may be suitable for structural repairs. Be careful though, not all neoprene-based shoe glues are created equal, especially for their resistance to water, temperature variations, and wear over time.

Epoxy glue is a synthetic resin found in formulas like Gorilla Glue or Boot-Fix – even if they contain other agents. It has the advantage of offering exceptional hold, even if it generally lacks a little flexibility. Its other advantage is its speedy and efficient drying. We prefer mixed formulas for shoe glues because the resin is often too rigid to hold over the long term.

Finally, there are all super glue-type shoe glues. A little more flexible than epoxy resin, and stronger than neoprene, its only drawback is that it costs a lot more and is of uneven quality. It is sold in bottles of only a few milliliters. We will also favor mixed formulas, such as Loctite PowerFlex which offers much more flexibility than a classic super glue.

Safety instructions

Most good shoe glues are solvent-based. This is particularly the case for formulas using neoprene. A few safety instructions must therefore be followed, the first being proximity to a flame or a heat source: some ingredients may be flammable depending on the formulas.

They can also cause discomfort, especially if mixed with other products when inhaling their vapors for a long time and in large quantities. It is therefore always advisable to handle these products in a well-ventilated room.

Tips for getting the best result

A few common-sense tips can help you get a better hold, regardless of the glue used. First, make sure to clean your work surface with a degreaser and/or cover it with newspaper. The vast majority of glues for shoes work best at room temperature, so it is preferable to apply it outside of extreme weather periods – very cold in a humid garage, for example, or a heat wave.

Next, carefully clean both sides of the shoe you are going to want to glue together. You can do this with an alcohol-based product, or non-residue surface cleaners.

The shoemaker's trick that achieves the best results is to scrape the smooth surfaces – metal, plastic, or rubber – typically found in the structural parts of the shoe with a bit of paper or glass. This increases the contact surface to a microscopic scale!

Remove the cap before applying pressure to the tube to reduce drips. If you simply apply the glue to one of the two surfaces to be attached, you will be able to dose more accurately.

The rest of the instructions will vary depending on the type of glue you use. In any instance, pressing the two components to be glued together for a variable amount of time and applying this pressure as rapidly as feasible will be required for a better result.

Regardless of the technique employed, allowing the glue to be set for 24 to 48 hours will yield superior long-term results.

Conclusion

Taking your shoes to a cobbler is not only expensive but also time-consuming. It is simple and quick to repair your shoes at home using the best glues on the market.

There are a variety of glues made expressly to assist you to repair your shoes; select one that gives good adhesion, and flexibility, is temperature and water resistant, and follow the manufacturer's directions while applying the glue.